Quartz Burners

We offer three types of quartz burners for different methods of optical fibre production:

AGI Quartz Burner

for OVD* and VAD**

Multiple Pipe Burner

for OVD* and VAD**

Multiple Nozzle Burner

for MCVD***

*Outside Vapour Deposition, **Vapour Axial Deposition, ***Modified Chemical Vapour Deposition

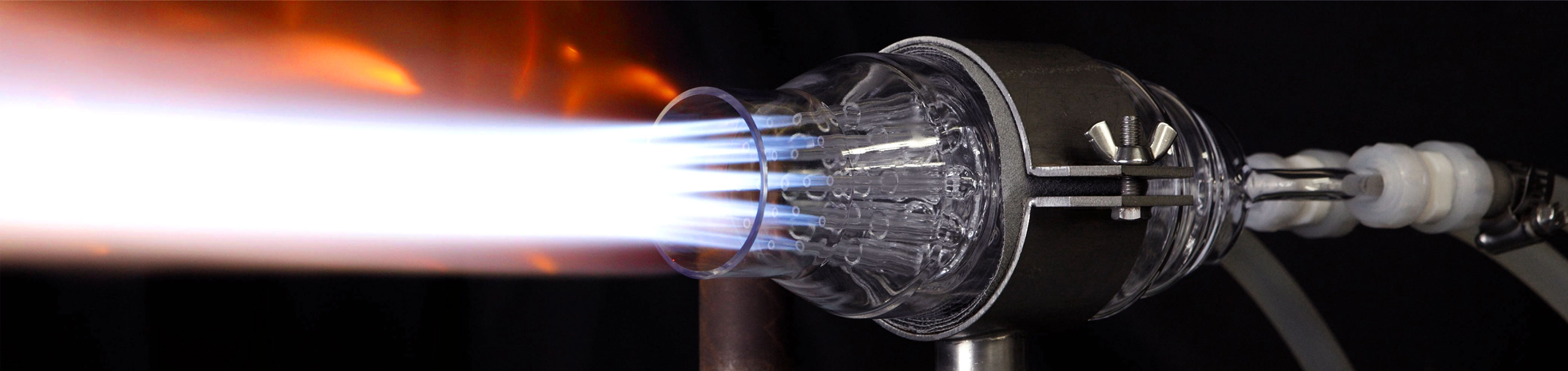

AGI Quartz Burner

for OVD and VAD

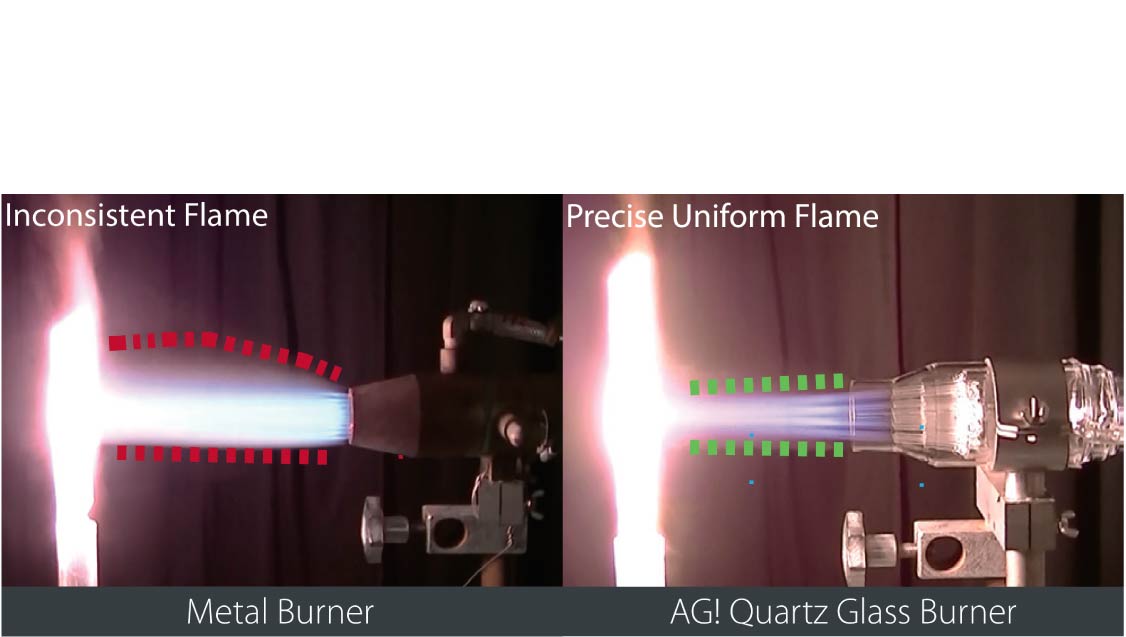

OVD and VAD methods for fibre optic cable manufacturing can benefit from our patented AGI Multiple Nozzle Quartz Burner (Japan Patent No. 3640071) as it provides a strong and stable flame with:

- High accuracy in flame focal length

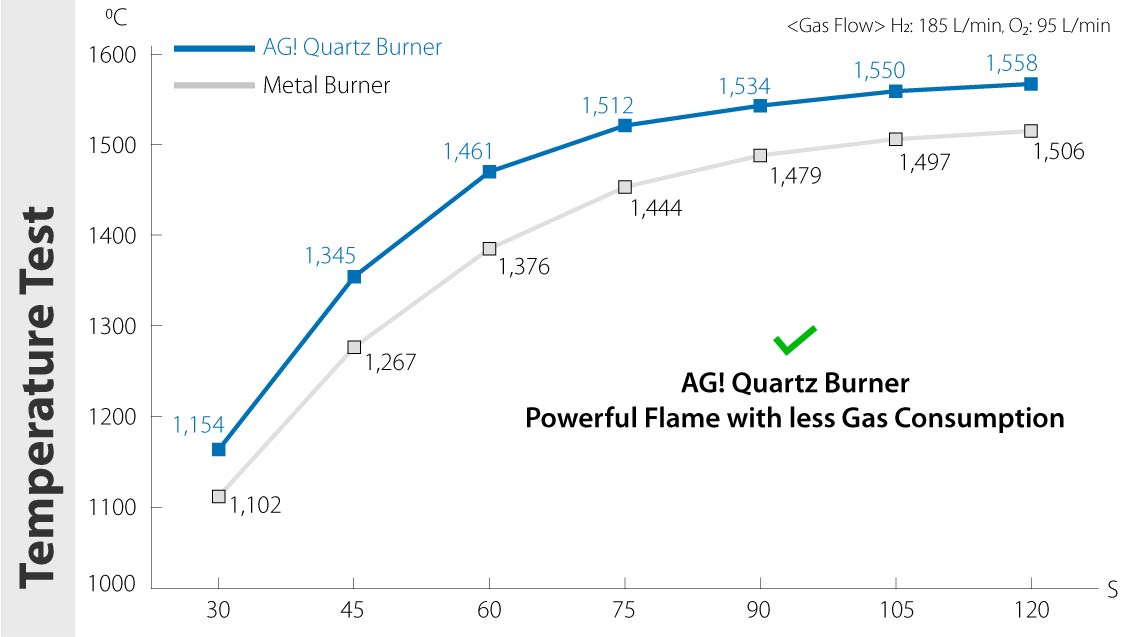

- High heat and efficiency

- Pure flame with zero contaminants

Highlights

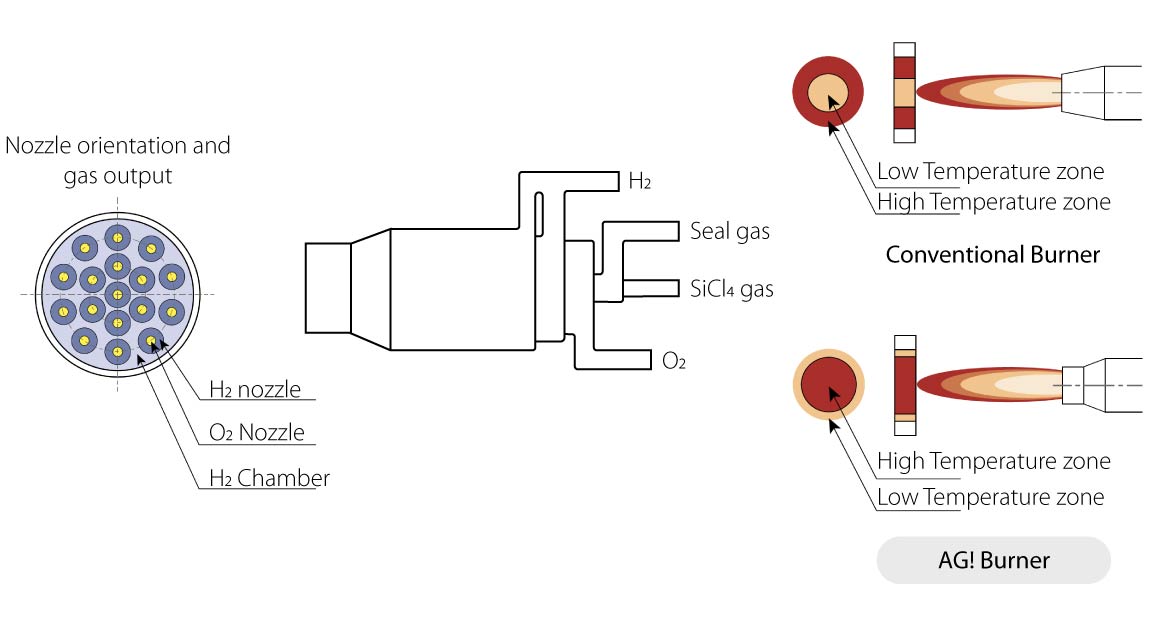

- AGI proprietary gas mixing provides superior heat, accuracy, and efficiency

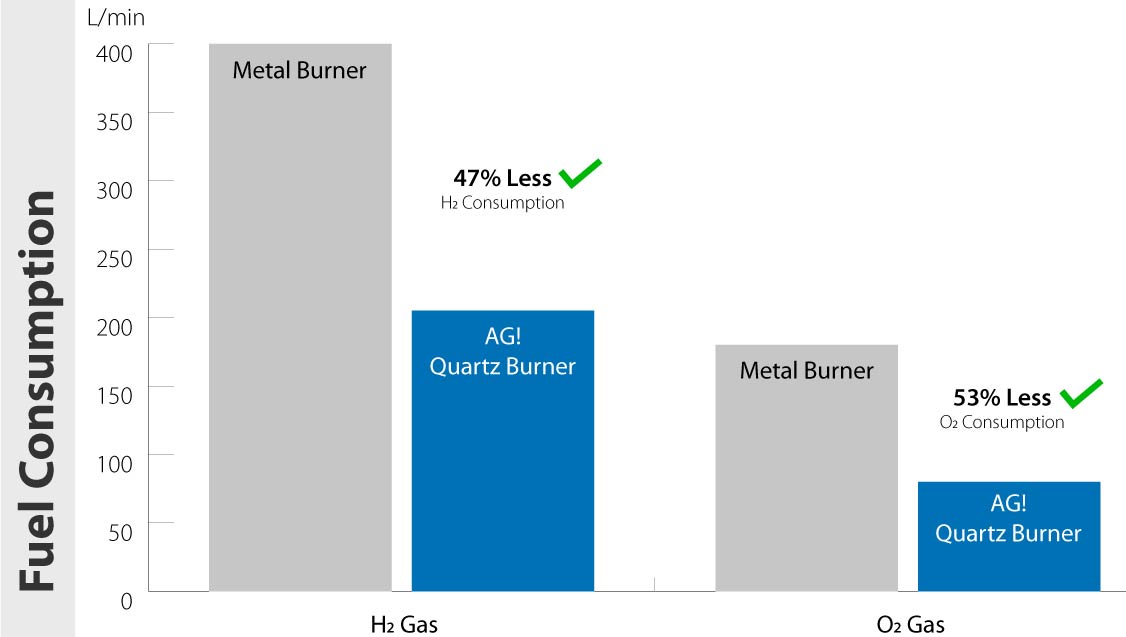

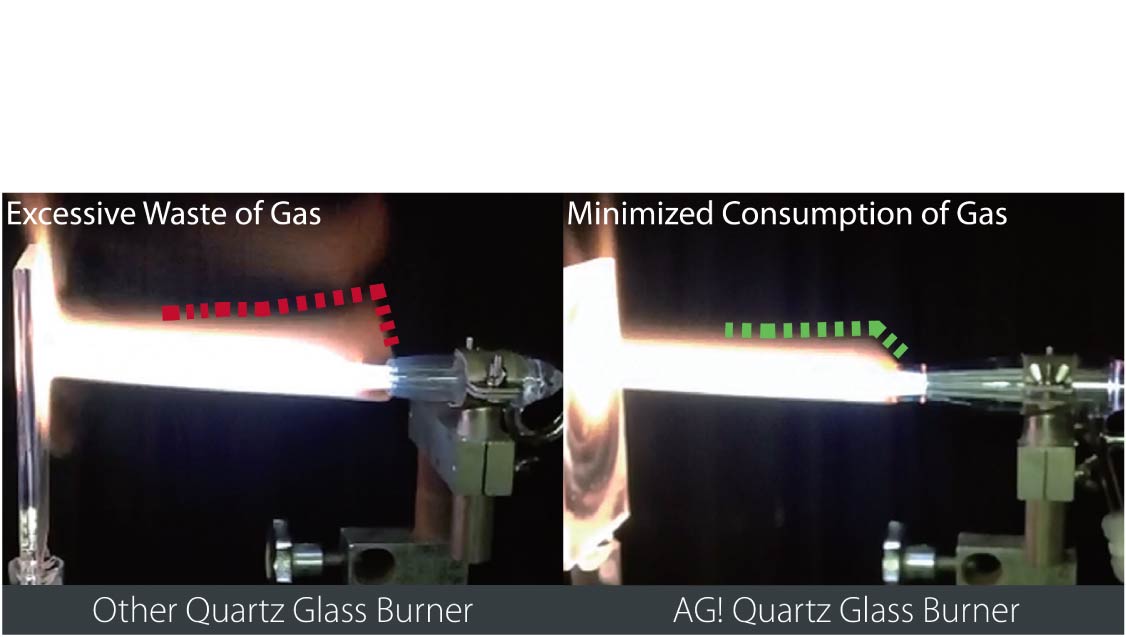

- Reduces gas consumption compared to conventional quartz and metal burners

- 100% quartz ensures zero contamination

- Each burner made by AGI is individually inspected and supplied with a 3D inspection report

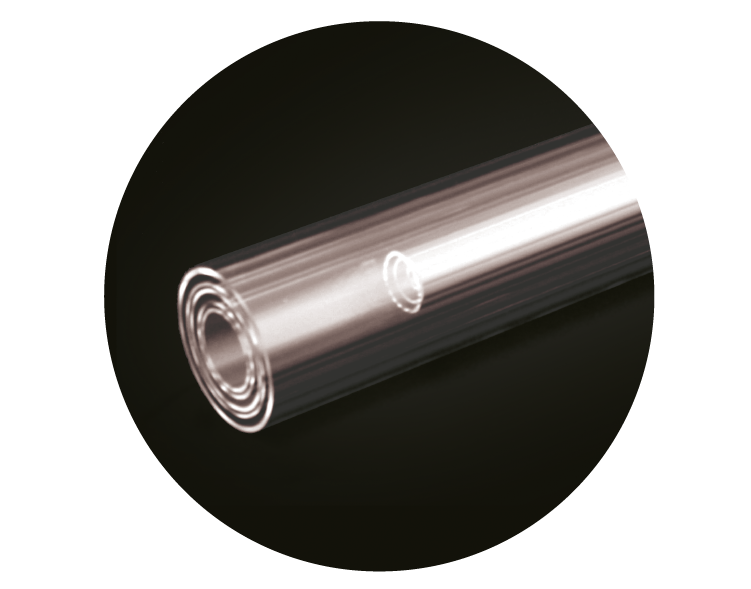

Configuration

- O2 nozzle is surrounded by H2 nozzle

- Accurate focal distance

- Max OD: 110 mm

- Custom design to suit focal distance and nozzle orientation is possible

- 3D inspection documentation for accuracy supplied with all burners

Proof of performance

Multiple Pipe Burner

for OVD/VAD

AGI Multiple Pipe Burner is useful for OVD and VAD methods of fibre optic cable manufacturing. Our Multiple Pipe Burner is available in range of different sizes and tolerances, with a maximum outer diameter of 130 mm. Each burner made by AGI is individually inspected and supplied with a 3D inspection report.

| Size | Tube Tolerance (Unit: mm) | Concentricity Tolerance (Unit: mm) |

|---|---|---|

| Up to 50 OD | ± 0.05 | ± 0.10 |

| Up to 80 OD | ± 0.10 | ± 0.15 |

| Up to 100 OD | ± 0.15 | ± 0.15 |

| Over 100 OD | ± 0.20 | ± 0.20 |

Multiple Nozzle Burner

for MCVD

AGI Multiple Nozzle Burner for MCVD method is made of quartz. The design of this burner produces a high efficiency flame and an accurate focal distance similar to AGI Quartz Burner for OVD and VAD methods. Each burner made by AGI is individually inspected and supplied with a 3D inspection report.

The right solution for you

AGI quartz burners and accessories are custom made to suit our customers individual application, and therefore would require a consultation in order for us to thoroughly understand what you need from your burner. Send us a message describing your application and any other relevant information and we will be happy to help.