The real performance driver

A well-performing jacketed vessel lets you achieve high yield and save energy and the time that you spend on your process. Ring Baffle helps you to achieve this.

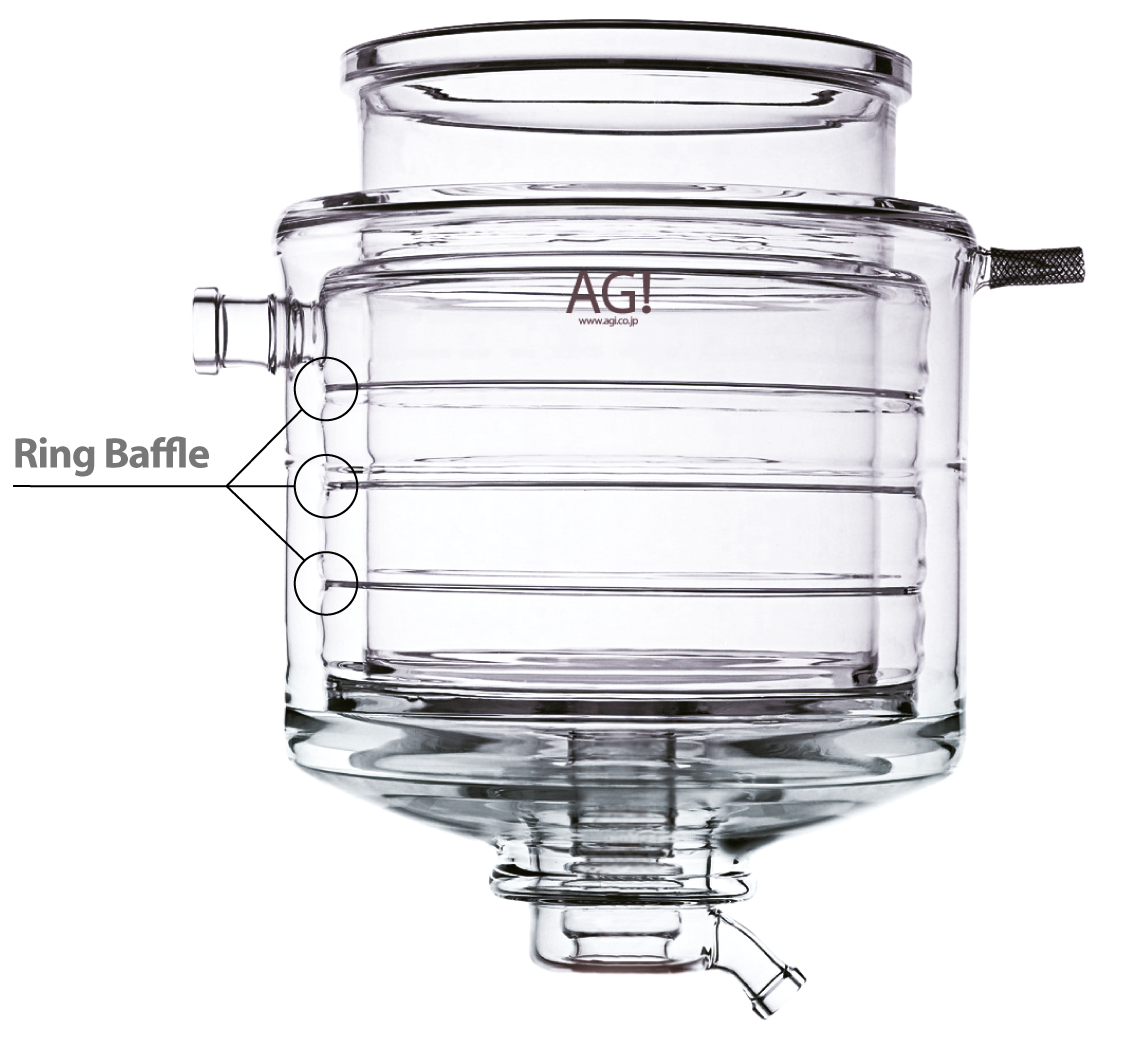

Ring Baffle is a unique feature available for jacketed glass vessels and is only offered by AGI. Ring Baffle is a series of ridge-like structures facing inward on the outer wall of the thermal jacket. The glass ridges direct the flow of thermal transfer fluid uniformly around the process vessel, and the uniform flow and local turbulence produced enhances the thermal exchange between the thermal jacket and process.

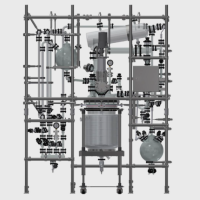

Cross-section of a jacketed reaction vessel with Ring Baffle

See how Ring Baffle distributes thermal fluid in the reactor jacket

In this video, a black dye is injected into the jacket of two reaction vessels with and without Ring Baffle, and the flow pattern of the dye is observed.

The Ring Baffle feature disperses the black dye uniformly in the jacket, but this effect is not achieved in the vessel without Ring Baffle, which displays uneven dye dispersion. This flow pattern is analogous to how heat energy would be dispersed in the jacket, and highlights how Ring Baffle technology contributes to the efficiency of your process.

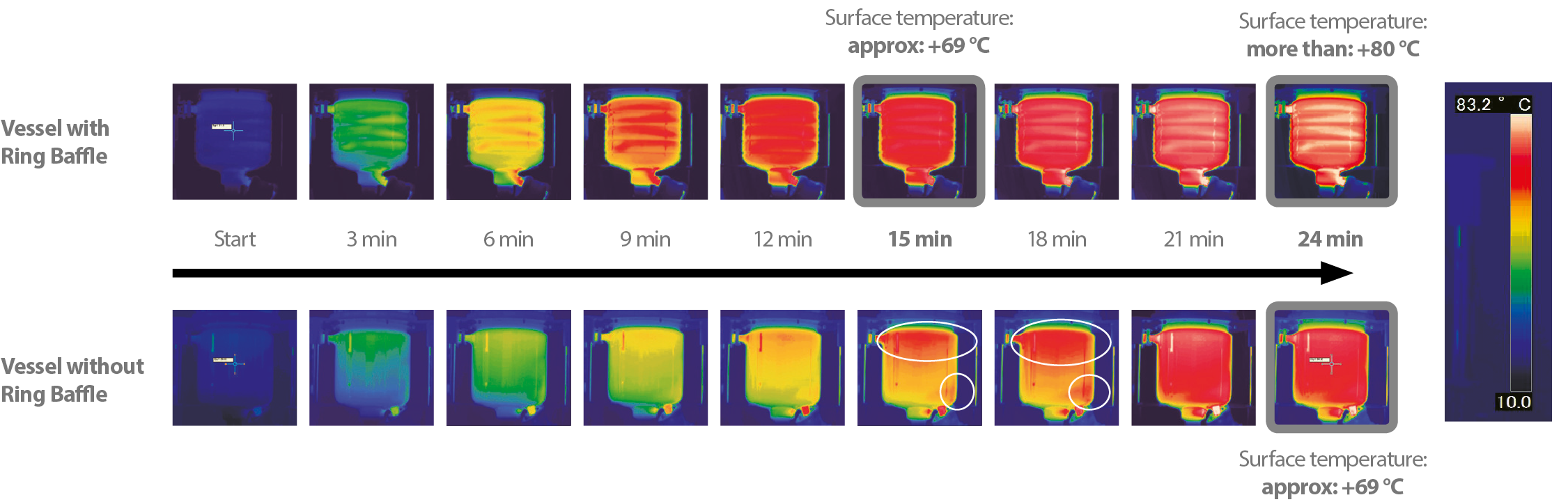

Heat distribution performance as shown by thermal imaging data

The image above shows a thermal image comparison between heating up two jacketed reaction vessels, with and without ring baffle, under the same conditions. This imaging method shows the heat map of the vessels.

The study shows that Ring Baffle evenly distributes thermal energy to efficiently heat the vessel. This can be seen above where the heat map is uniform from the 15 minute mark for the vessel with Ring Baffle. The vessel without Ring Baffle has uneven thermal spots across all the data points measured. This illustrates the heat distribution efficiency of Ring Baffle.

Benefits of Ring Baffle

Ring Baffle helps you save time

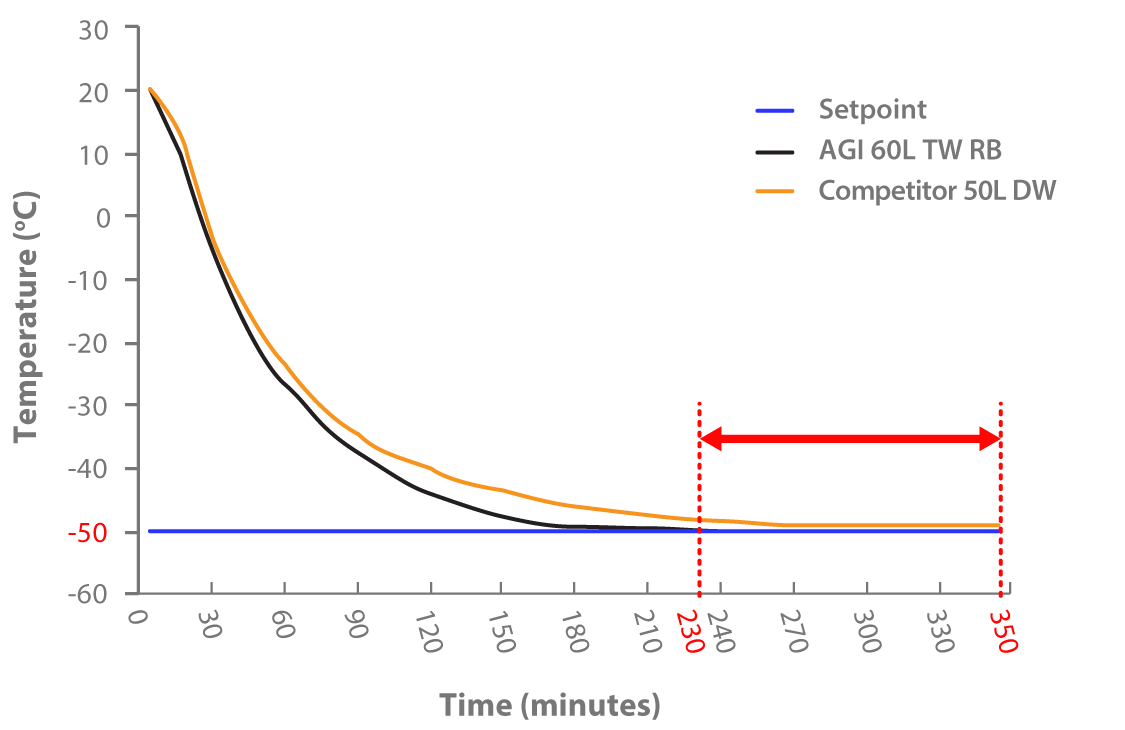

AGI Triple Wall Ring Baffle 60 L Reactor vs

Competitor Standard Double Wall 50 L Reactor

Cool 120 mins faster

Thermostat: HUBER Unistat 510w, HTF: silicone oil

Verdict: The set process temperature, -50 °C, was achieved 120 minutes faster in the AGI Reactor. It is important to note that the competitor reactor volume is 10 L smaller.

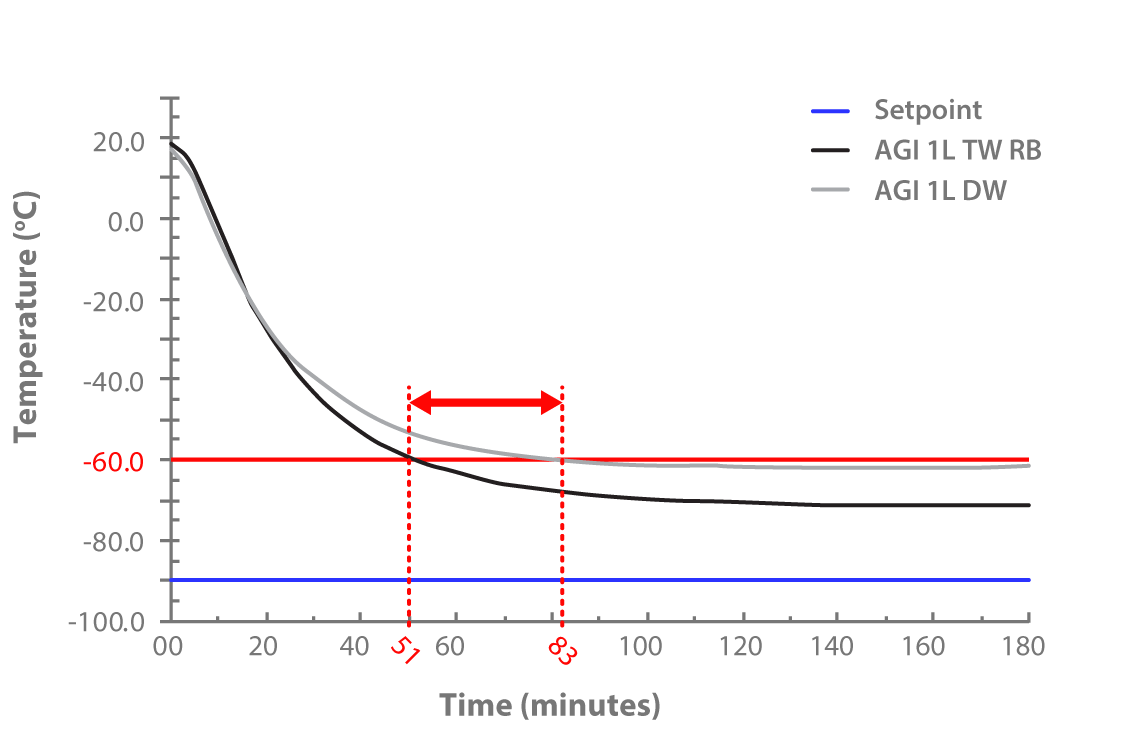

AGI Triple Wall Ring Baffle 1 L Reactor vs

AGI Double Wall 1 L Reactor

Cool 30 mins faster

Thermostat: LAUDA RP890C, HTF: silicone oil

Verdict: Although the set process temperature was not achieved, -60 °C was achieved 30 minutes faster in the AGI triple wall reactor compared to the double wall reactor.

Ring Baffle offers better thermal exchange

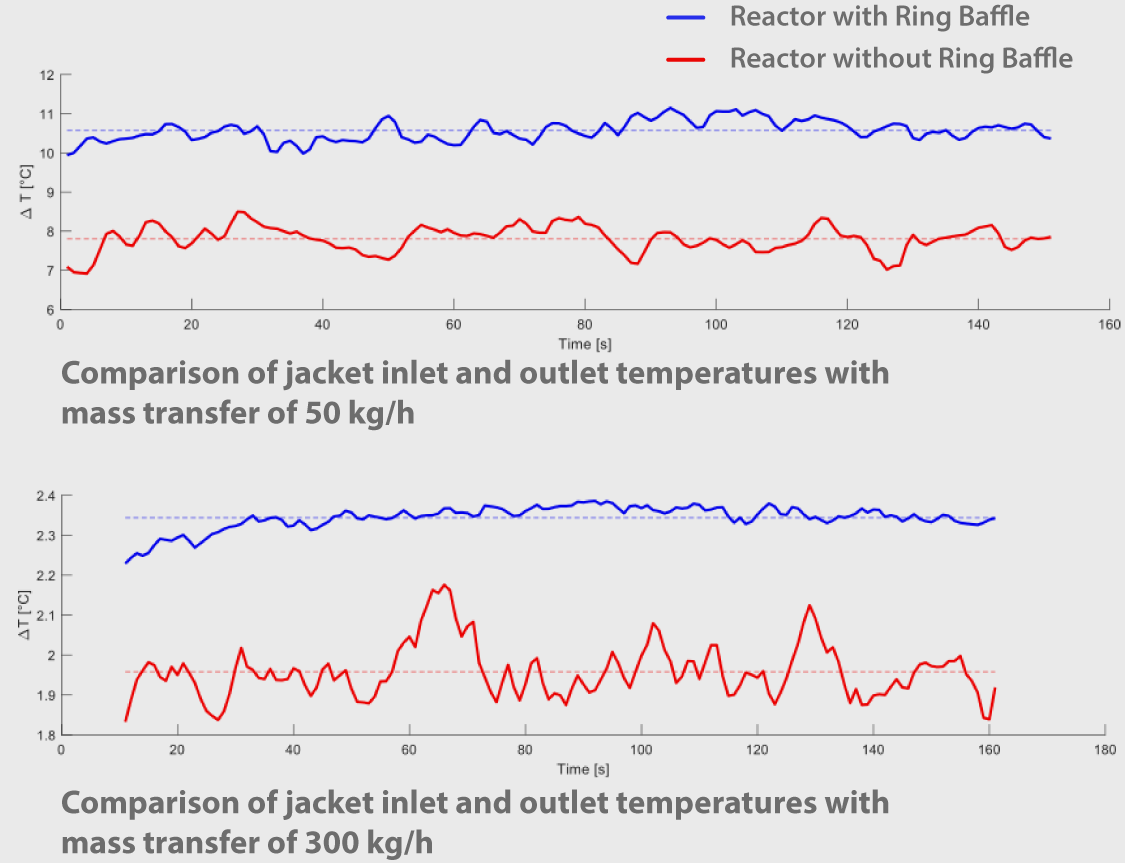

In this study, the performance of heat transfer efficiency of AGI reactors with and without Ring Baffle demonstrated that the presence of Ring Baffle facilitated better heat transfer.

How was it done?

3 L AGI triple wall reactors with and without Ring Baffle were used with an identical set up. An endothermic reaction was emulated in the vessels by stirring 1 kg of water with 2 kg of ice. The thermostat was set to +40 °C and the temperatures at the inlet and outlet of the thermal jacket in both reactors were measured at mass flow from 50 kg/h to 400 kg/h by adjusting the agitation rate.

Result

The ΔT (difference in jacket inlet and outlet temperature) of vessels with and without Ring Baffle were plotted against time. The result showed that the vessel with Ring Baffle consistently had higher ΔT at all mass flow rates, compared with the vessel without Ring Baffle.

This shows that Ring Baffle provides better heat transfer capacity to AGI vessels.

Study was conducted at Hochschule für Life Sciences FHNW, Muttenz, Switzerland

Ring Baffle offers better crystallisation performance

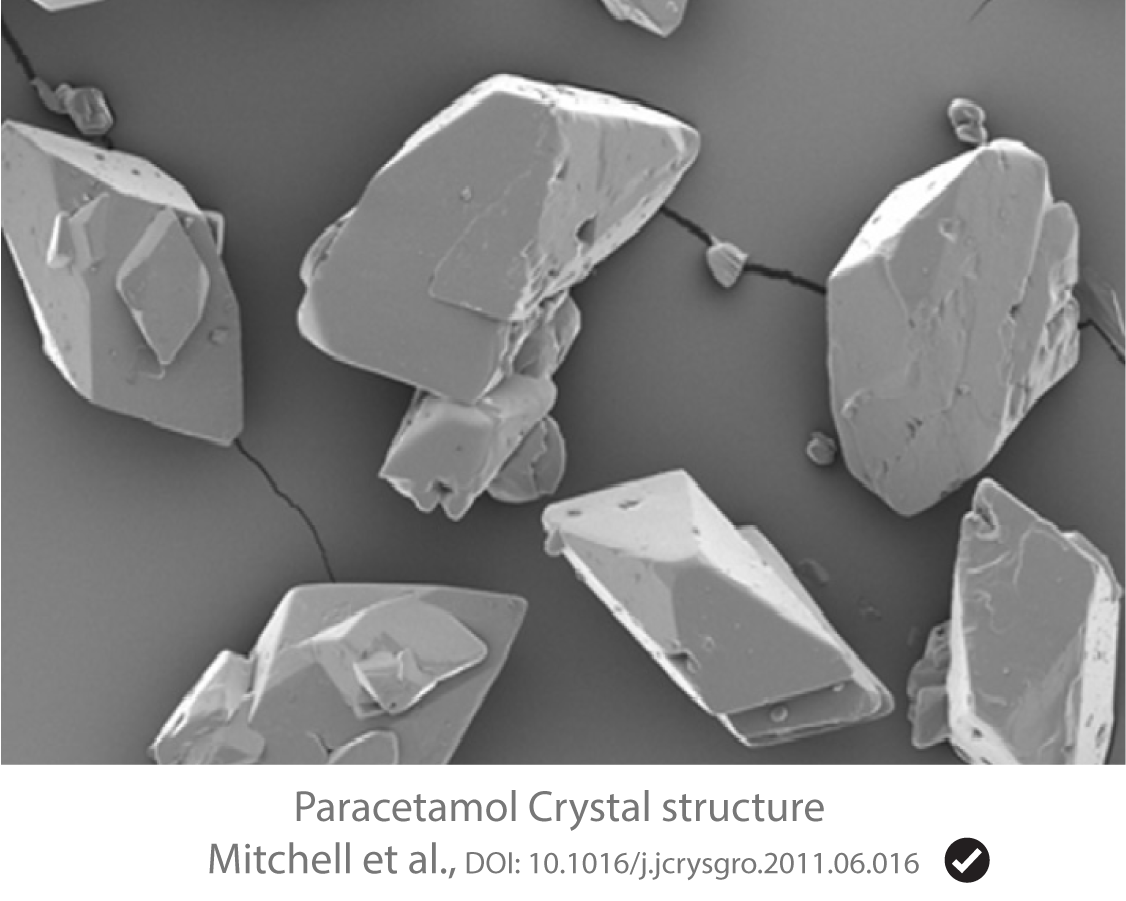

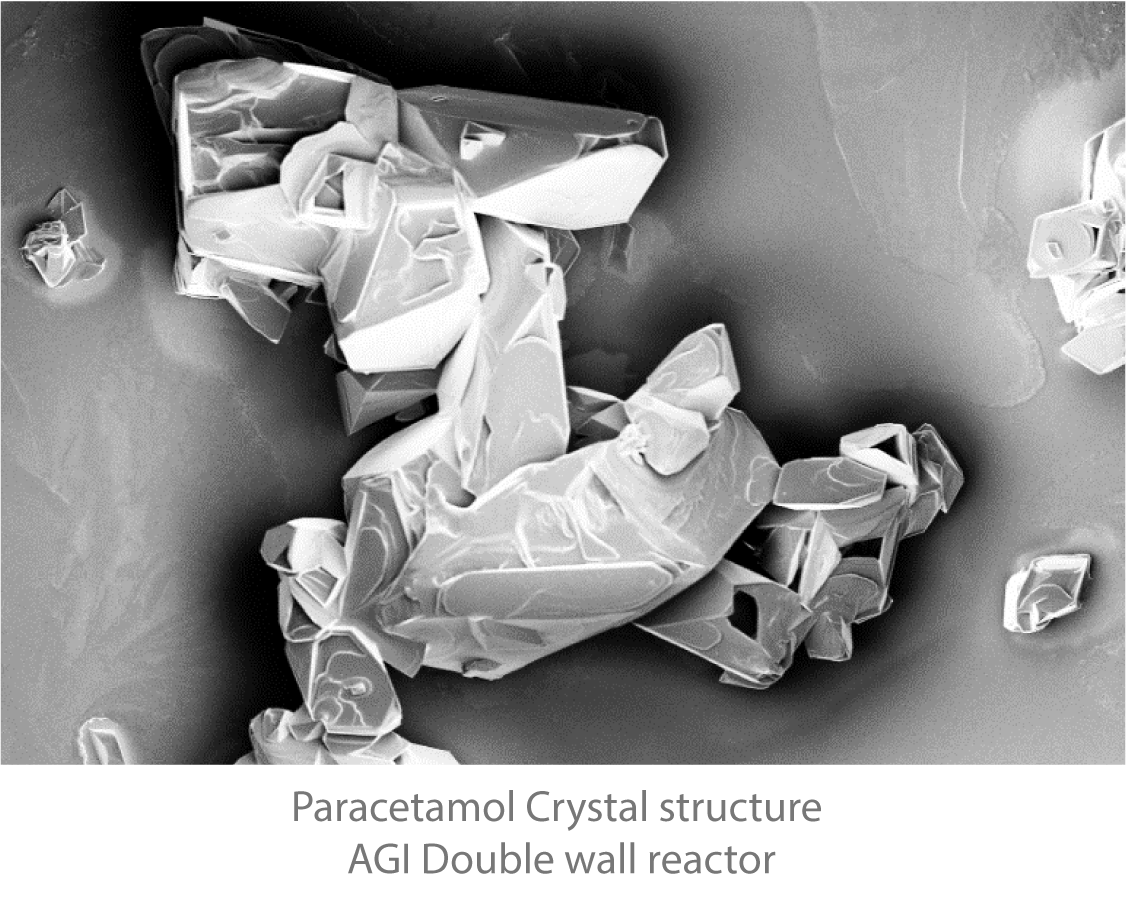

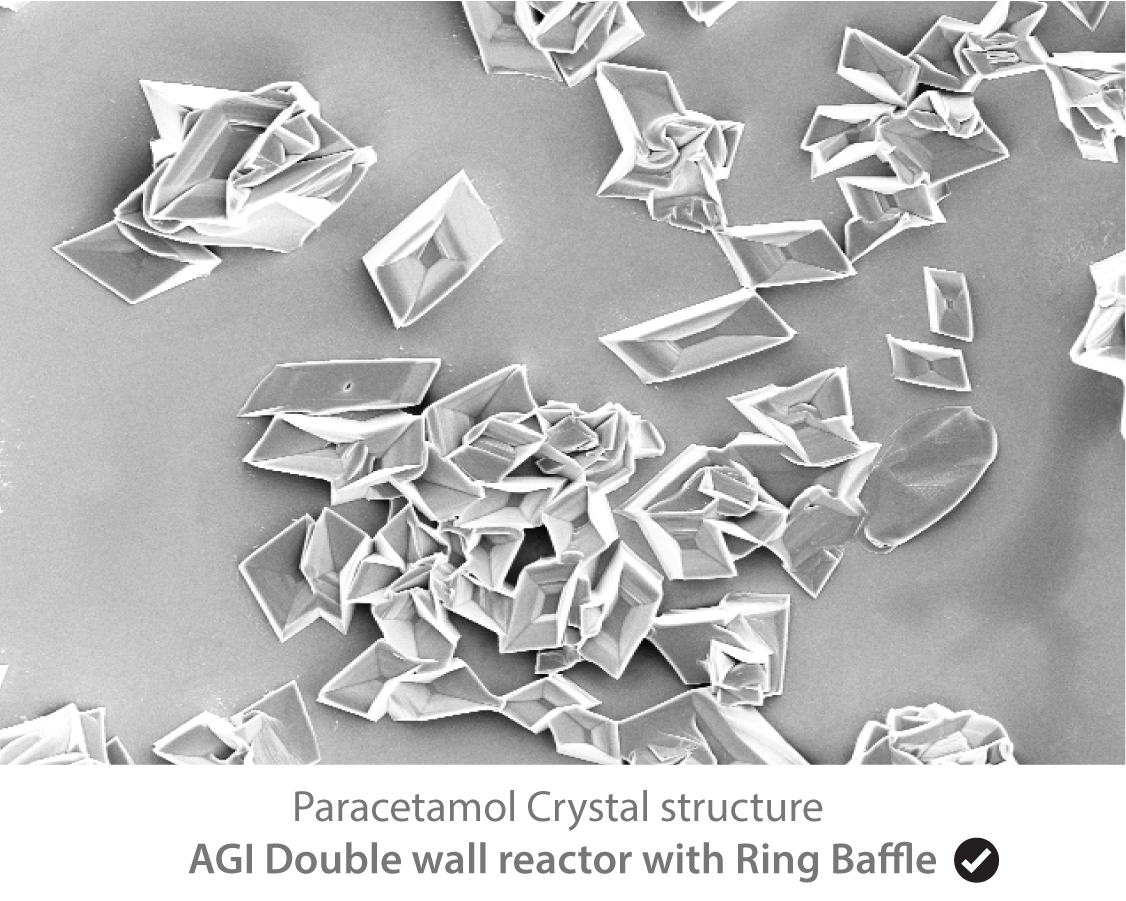

Crystallisation of paracetamol was compared using AGI double wall reactors, with and without Ring Baffle, using established methods.

How was it done?

Paracetamol was suspended in ethanol and heated to 60 °C while stirring. The suspension was then cooled down to 20 °C. Seeding crystals were added to the suspension with constant stirring and the temperature was held at 20 °C for an hour. The resulting crystals were filtered, dried, and examined for structure.

Result

The crystal structure obtained from AGI reactors with and without Ring Baffle were compared with a previously published structure.

The AGI reactor with Ring Baffle produced a comparable crystal structure to the published structure than the crystals from the vessel without Ring Baffle. We attribute the superior performance of AGI reactors with Ring Baffle to the precise temperature control that it offers.

Case studies using AGI vessels

Select a volume below