Rotary Evaporator

Robust construction and sealing

AGI Rotary Evaporator is designed with industrial use in mind. The components are durable and highly chemically resistant, with reinforced PTFE mechanical sealing and bearing connecting the flask to the rest of the structure.

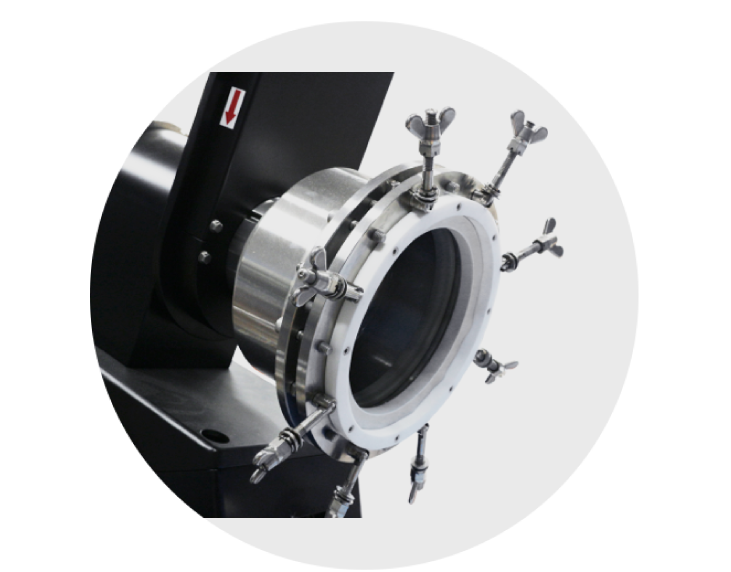

Reinforced PTFE Mechanical Seal and Bearing

Easy handling of large flasks

For flask capacities of 50 L and above, a handling cart is available, which makes it easy to transport, empty, and clean flasks.

Handling cart makes it easy to transport, empty and clean flasks

Debris-free operation

The mechanical sealing on AGI Rotary Evaporator is made of carbon-reinforced PTFE which provides a practically shred-free operation. Thermal expansion of PTFE, steel and ceramics are taken into consideration in the seal design, which also increases the durability and life of the sealing.

Debris free operation is ideal for continuous operation

Easy maintenance

AGI Rotary Evaporator is designed to be easily maintained and cleaned. Sealing alignment can be achieved simply by adjusting a screw in the seal. Centring of the flask is guided by the PTFE centring adapter, which enables easy centring with a deviation of just 0.25 mm. These features ensure that the potential for user error is minimised and that the evaporator takes less time to set up.

Sealing alignment and adjustment can be done very easily

Other features

AGI Rotary Evaporator has other useful features, such as a sampling port in the flask for easy sample collection, an external shower to cool down or maintain temperature of the flask, and rolling coasters for easy displacement.

The right solution for you

AGI Rotary Evaporator is bespokely constructed for our customers individual process requirements, and therefore would require a consultation in order for us to thoroughly understand what you need from your evaporation system. Send us a message describing your process and any other relevant information to kick start the conversation.