Pilot Plant Reactor

Effortless operation

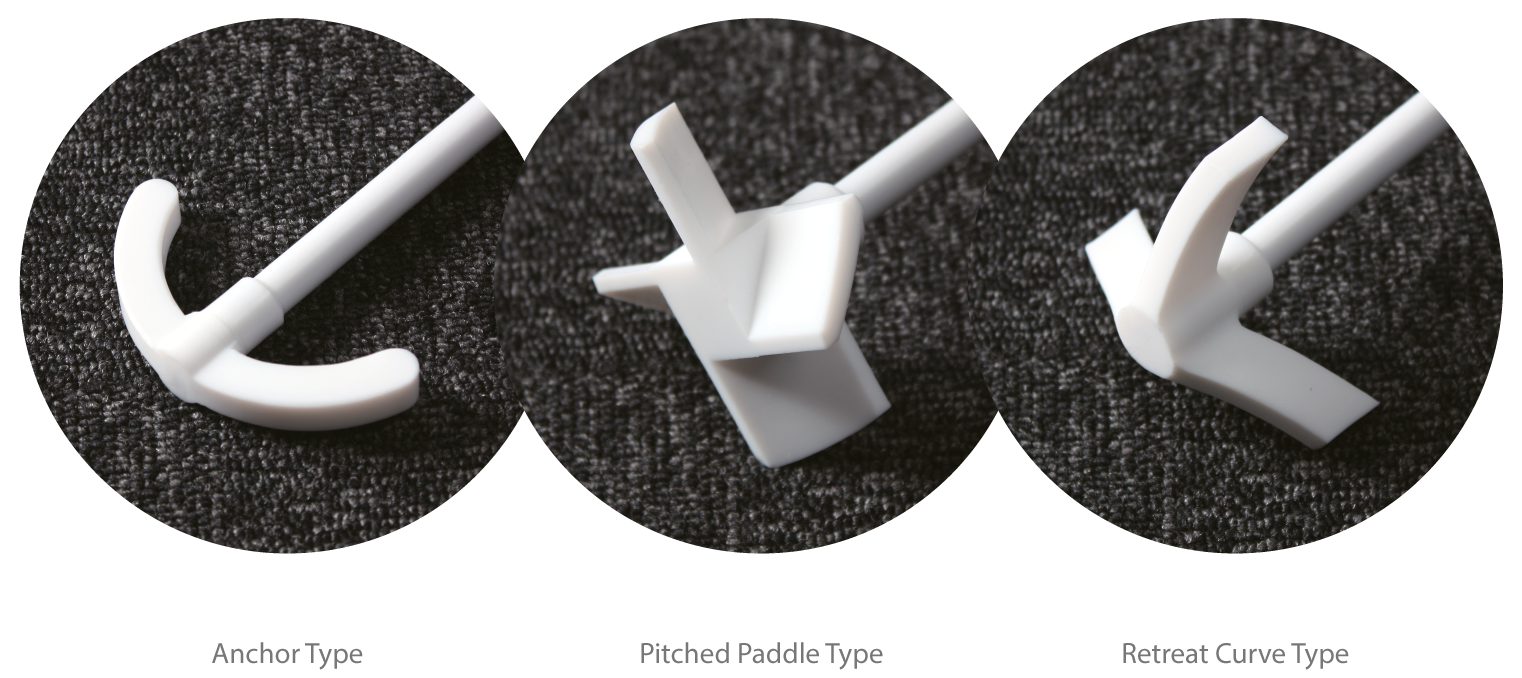

What sets AGI Pilot Plant Reactor apart from other reaction systems is its superior support structure. Accessories for production and process development applications are mounted on a PFA coated, flat SS lid, and the vessel is mounted to the support structure using a special lever mechanism. With minimal effort, this mechanism allows for easy displacement of the vessel; it can be moved up, down, and sideways.

Accessories for process development

AGI Pilot Plant Reactor is best suited for kilo lab/pilot plant production applications, along with process development. The PFA-coated SS Lid has adaptable multipurpose 40 A ports with accessories such as purge port, pressure gauge, hand hole, safety valve, condenser, dropping funnel, condensate cooler, condensate receiver, stirrer seal, and temperature sensor. These accessories help to fine tune the reaction and create an optimal process.

Note: 10 L models have vertical condenser. 20 L and 30 L models have diagonal condensers.

Numerous accessories provide safety, facilitate monitoring and control of process. All ports are multi-purpose 40 A

Ring Baffle - a performance driver

A well-performing reactor achieves high yield and saves both energy and the time that you spend on your process. Ring Baffle helps you to achieve this.

Ring Baffle is a unique feature available only from AGI. It is a series of ridge-like structures in the thermal wall of the reactor vessel which direct the flow of thermal transfer fluid uniformly around the process vessel.

The uniform flow and local turbulence produced by Ring Baffle enhances the thermal exchange between the wall and process. This effect is not possible in vessels that don't have Ring Baffle.

This video shows the flow pattern of a black dye in thermal jacket with and without ring baffle. Ring baffle distributes the dye more evenly compared to the vessel without the ring baffle.

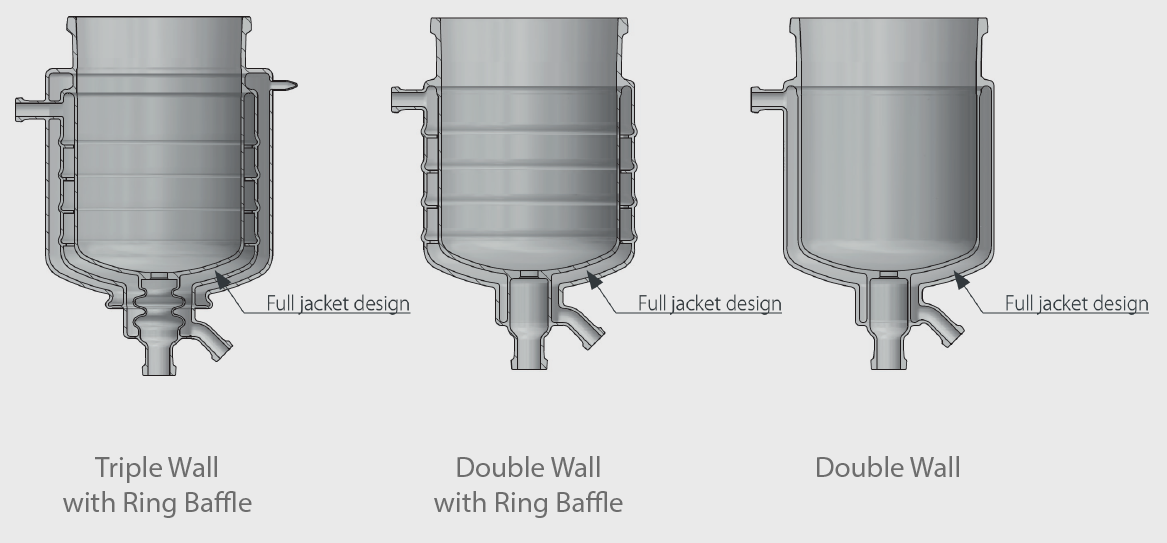

High performing reaction vessels

Vessels are a core component of a reaction system. AGI glass vessels are available with a double wall (thermal) jacket or triple wall (thermal and vacuum) jacket. Both types are available with or without Ring Baffle. All vessels made by AGI have thermal jackets up to full working volume.

Optimized for excellent heat transfer

The inner vessel wall thickness is optimized using AGI’s propriety resizing method. The benefits of this are:

- Improved thermal exchange

- Reduction of energy expenditure

- Improved process temperature control

Complete jacket cover

Our pilot scale vessels have thermal jackets that cover the process vessel completely. The benefits of this feature are:

- Efficient use of thermal energy

- Complete immersion of process in set-point temperature

- Better product yield due to uniform and consistent temperature treatment

High thermal shock resistance

Our double and triple wall vessels have the best thermal shock resistance (ΔT) for glass reactors available on the market. This allows for versatility in your process and marks the performance factor of our vessels.

- ΔT for double wall vessels: 110 °C

- ΔT for triple wall vessels: 60 °C

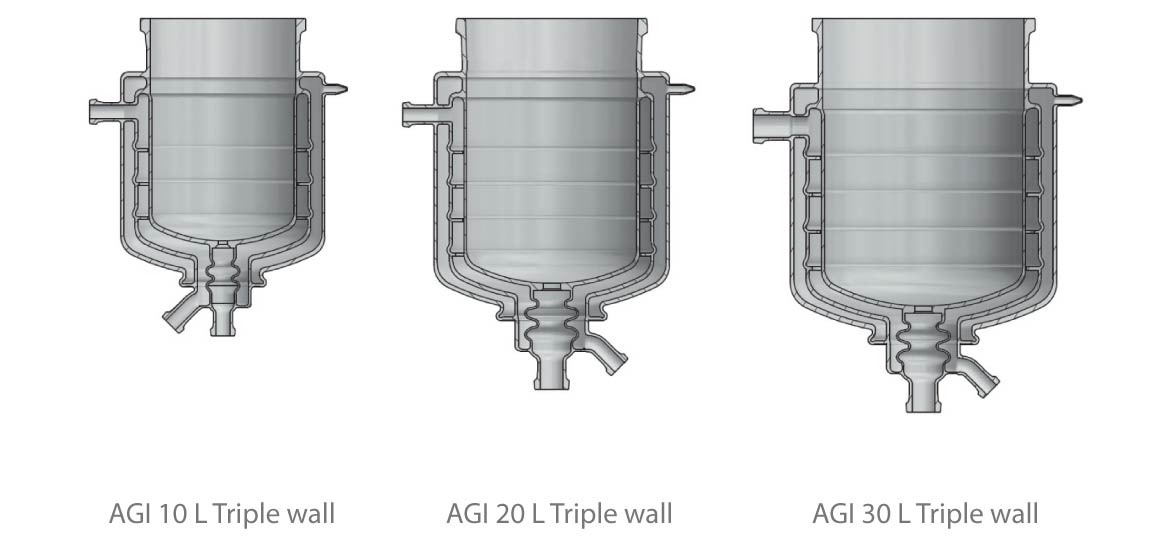

Scale up with ease

AGI reaction vessels are designed with scale-up in mind. Our triple wall vessel geometry closely resembles the geometry of industrial glass-lined reactors.

| AGI Triple Wall | Competitors |

| Aspect ratio ID (W) : Height (H) | 1:1 ~ 1:1.5 | 1:1 ~ 1:2.5 |

| Bottom Shape | Similar to that of conventional glass lined reactors (10% head plate) | Round Bottom |

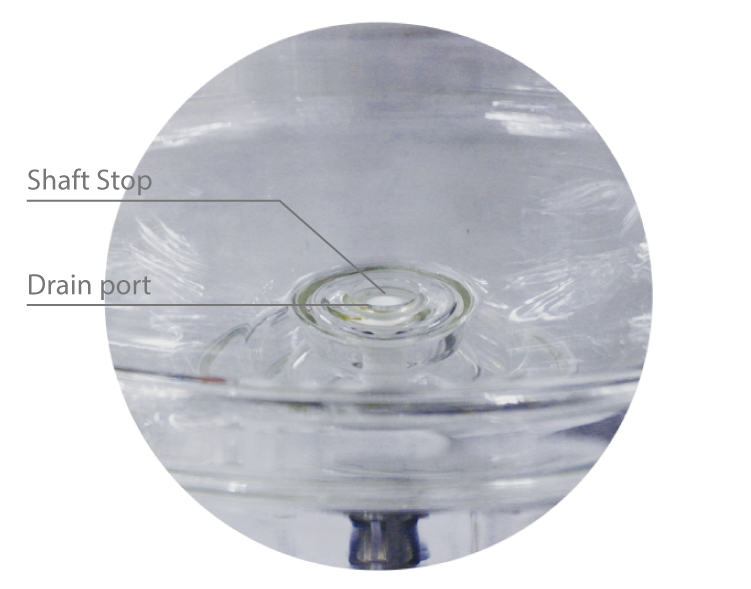

Minimal dead space

The perfect alignment of a flush valve and its PTFE shaft with the drain port of the reaction vessel provides a continuous surface that leaves negligible dead space. This way, there is minimal stagnation and everything is in movement during agitation.

Easy to clean

Cleaning a reactor should be easy in order to keep your workflow simple and prevent cross-contamination from batch-to-batch. Our reaction vessels are designed with this in mind.

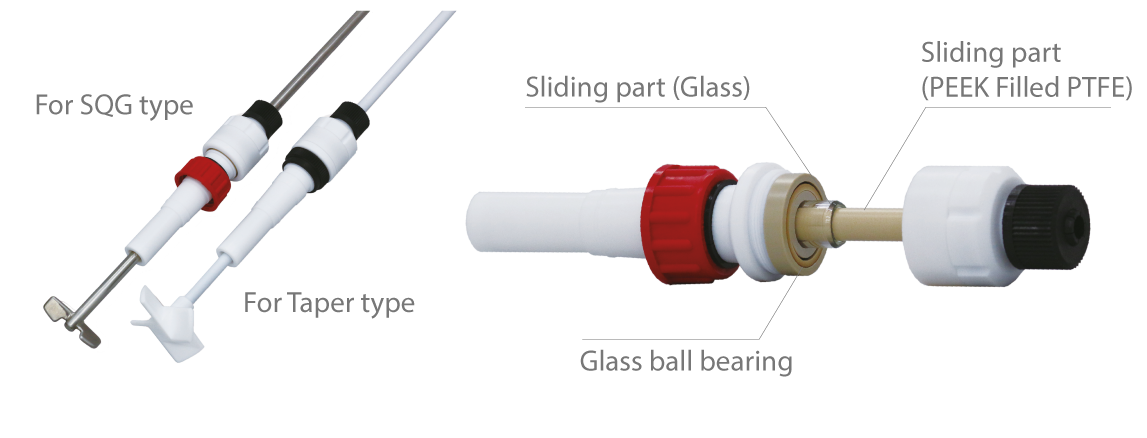

Stable and debris free stirring

Newly designed AGI stirrer bearings have an extended configuration with glass and PEEK sliding parts. For pilot plant reactors, taper type stirrer bearings are used.

Stable stirring

The stirrer bearing design reduces axial deviation of impeller at high RPM, resulting in stable, wobble-free stirring.

Video demonstrating how the impeller wobbles using conventional (Left) and AGI (right) type stirrer bearings at different RPMs

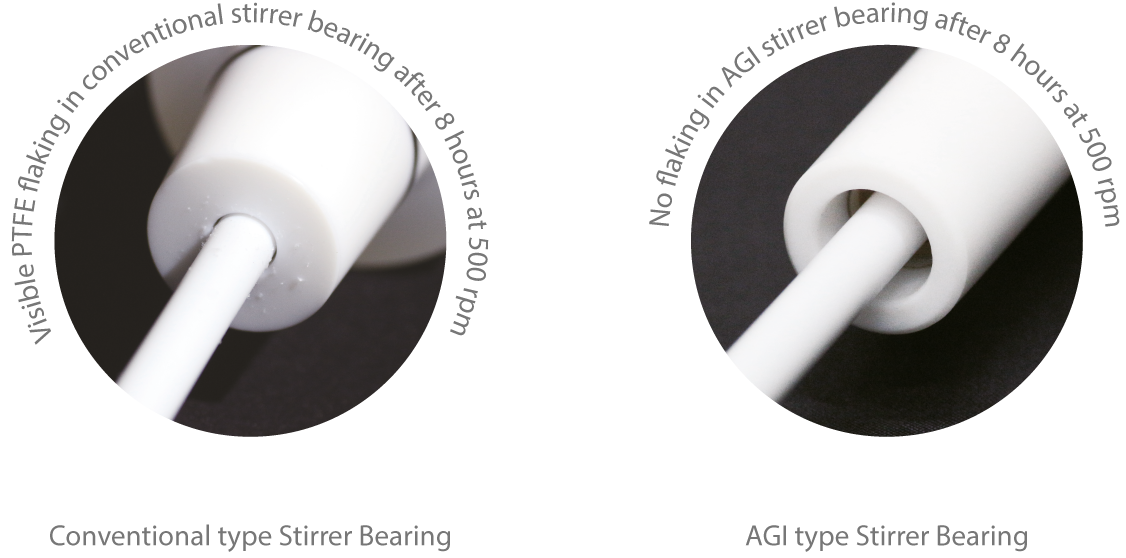

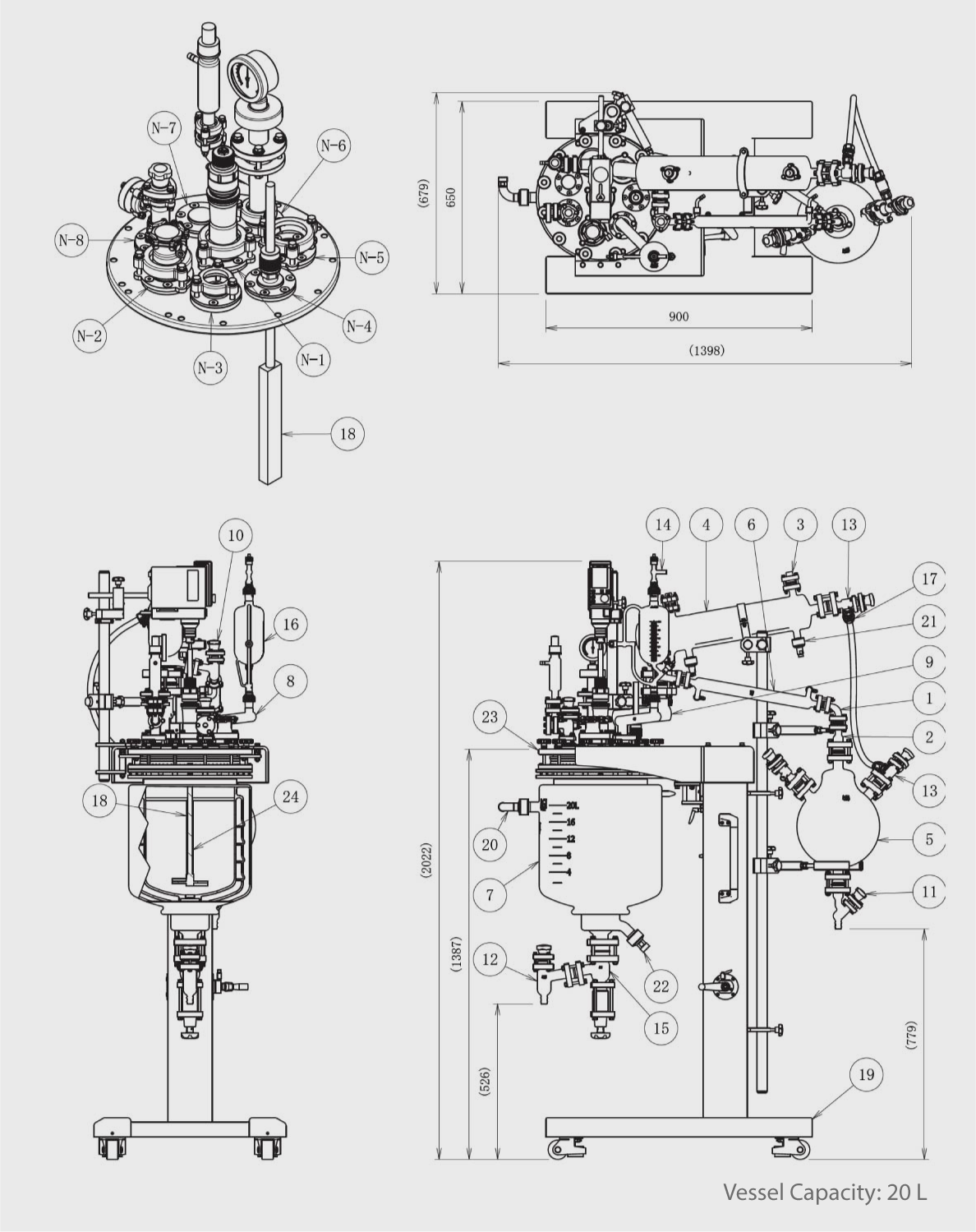

Debris free stirring

Our testing showed that the AGI stirrer bearing has reduced PTFE flaking (from stirrer shaft) with prolonged operation compared to conventional bearings available in the market.

Stable stirring

The stirrer bearing design reduces axial deviation of impeller at high RPM, resulting in stable, wobble-free stirring.

Video demonstrating how the impeller wobbles using conventional (Left) and AGI (right) type stirrer bearings at different RPMs

Debris free stirring

Our testing showed that the AGI stirrer bearing has reduced PTFE flaking (from stirrer shaft) with prolonged operation compared to conventional bearings available in the market.

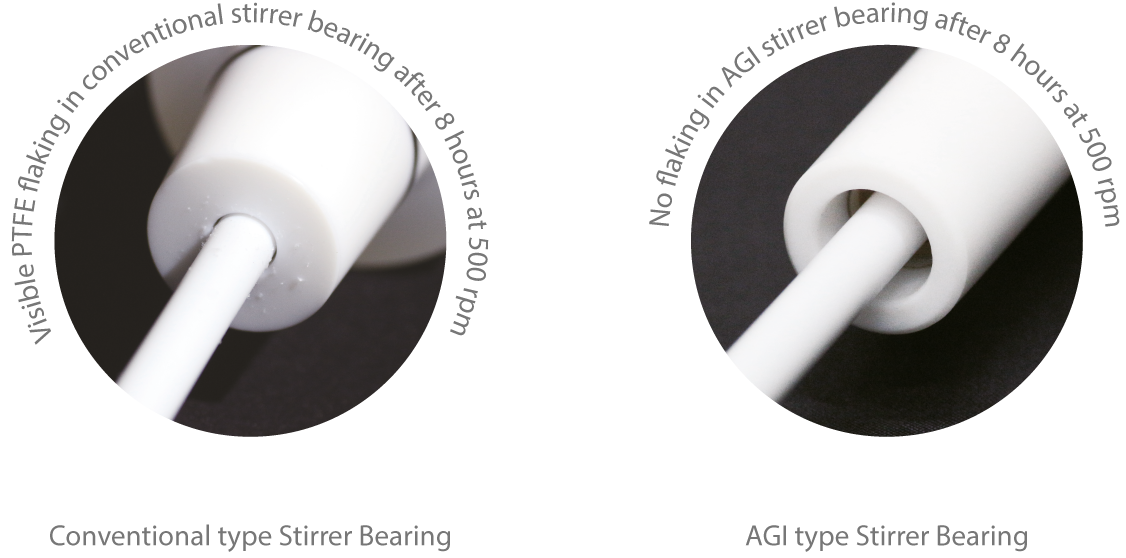

Impeller options

Mass flow pattern is an important factor to consider when you want to achieve a perfect chemical reaction process. We offer three types of impellers with axial or tangential flows. AGI impellers are made of SS rods encapsulated in PTFE for excellent chemical resistance and mechanical strength. If your application requires a special flow, see our advanced impeller options. If you find these are not sufficient, please contact us and we can help you to find a solution that suits your specific process.

Standard package

- Bend Adapter (80°)

- Reducer

- Thermometer Pocket

- Condenser with Reflux Divider

- Receiver

- Product Cooler

- Vessel

- Adapter (SQG 24/40)

- Adapter (40 A, 50 A)

- Straight Valve, L Type

- Drain Valve (PVD 25, ф20)

- Drain Valve (PVD 25, ф20)

- Vacuum Vent Valve (PVH 25, ф19)

- Greaseless Valve (SQG 24/40)

- Flush Valve

- Dropping Funnel

- Fitting

- PTFE Stirrer Shaft, Shaft OD: 16 mm

- Support Structure

- Metal Adapter for HTF, M30

- Adapter for HTF, 15 A

- Metal Adapter for HTF, M30

- Cover Plate, SUS304, PFA coating

N-1 Port for PTFE Stirrer Guide

N-2 Hand Hole

N-3 Port for Dropping Funnel

N-4 PT100 Sensor with Holder

N-5 Port for Condenser

N-6 Compound Pressure Gauge, Safety Valve

N-7 Spare Port

N-8 Purge Port (Rc 3/8)

* Ports on Cover Plate: 7 Ports (10 L), 8 Ports (20 L, 30 L)

* 8 Ports include a Spare Port

* All O-rings are consumables parts.

* Overhead stirrer motor is not included.

Something else in mind?

At AGI, we can help to find the best solution for you. If you have additional requirements or a design already in mind, feel free to send us a message and/or drawing so that we can understand your process better and provide you with a customised product that meets your exact needs.