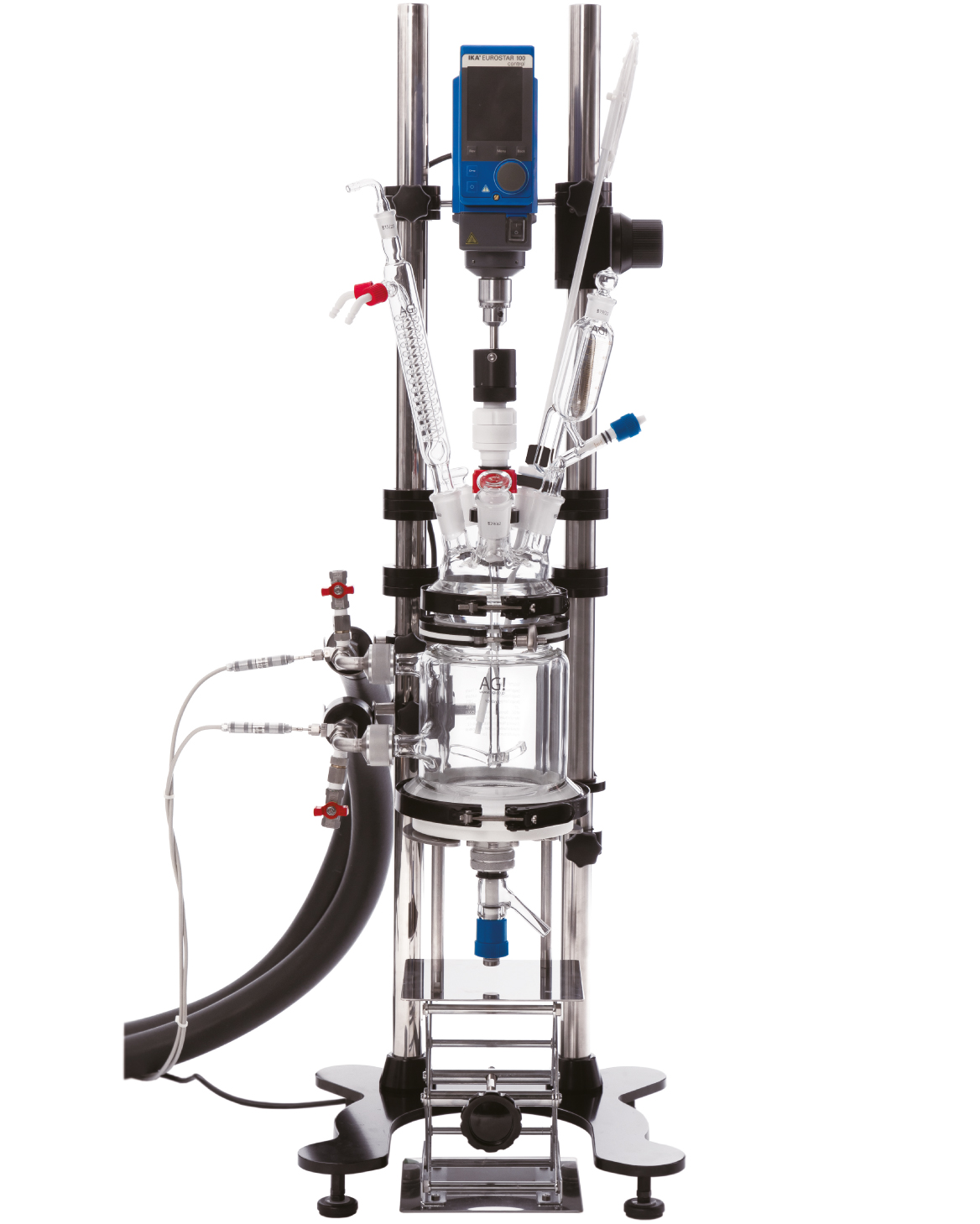

Benchtop Filter Reactor

AGI Benchtop Filter Reactor can be fitted with a number of optional accessories that improve ease of use and functionality. If you have any questions about these accessories, feel free to contact us.

Benchtop filter reactor - 1 L

Double wall

All optional accessories assembled

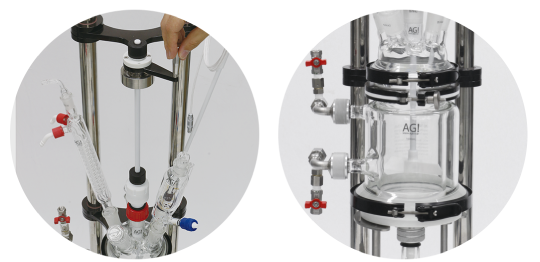

Lift assist mechanism

As the name suggests, this mechanism helps you to easily lift or lower the over-head stirrer motor and the filter vessel, and requires minimal effort to adjust the knob to fix the desired position. This feature is beneficial for easy operation when space in the fume hood is limited.

Note: Two knobs are present for overhead motor and the vessel. Height adjustment must be done independently.

Lid holder

The lid holder holds the lid on the support structure when you remove the vessel. This option helps to maintain a clean work space and eliminates the risk of breaking the lid or lid accessories during vessel replacement or cleaning.

Buffer tank

Buffer tanks are useful for collecting the filtrate that comes out of the drain valve. Supplied with connections to the drain valve and vacuum pump, they can be connected to a vacuum source for vacuum-assisted filtration. Different capacities are available based on your need. Please contact us for details.

Manual stirring setup

Motorised stirring can be replaced with manual stirring for gentle and controlled stirring. This option can be particularly useful for situations where the product cake is large and requires smoothening for even washing and breaking of cake for slurry formation and powder dispersion.

Flexible bearing coupling

The newly designed flexible bearing coupling eliminates a common stirrer shaft - motor alignment problem by connecting the stirring motor and impeller. With this coupling, even if the alignment of motor and stirrer shaft drifts during the operation, the wobbling of the impeller is eliminated.

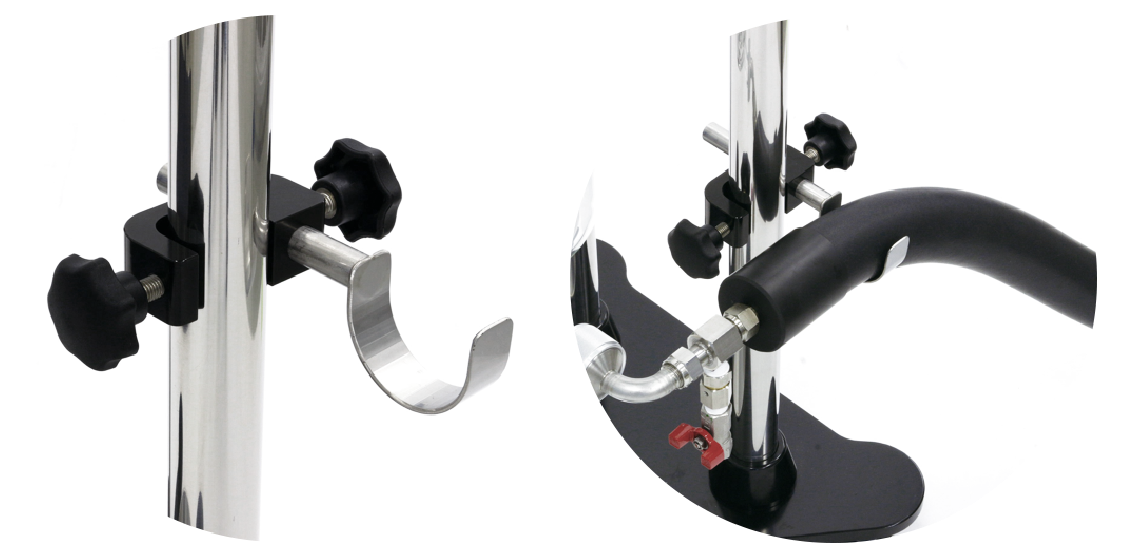

Insulated flexible hose

Highly flexible insulated hose gives you the advantage of installing the reaction unit in tight spaces. The high-quality insulation provides minimal loss of thermal energy compared to standard insulated hoses.

Hose support clamp

When connected to the reactor jacket, some insulated hoses can cause stress on the glass inlet and outlet. A hose support clamp reduces this stress and protects the glass inlet and outlet ports, providing extra safety.

Support Clamp removes stress on the glass inlet and outlet of the thermal jacket

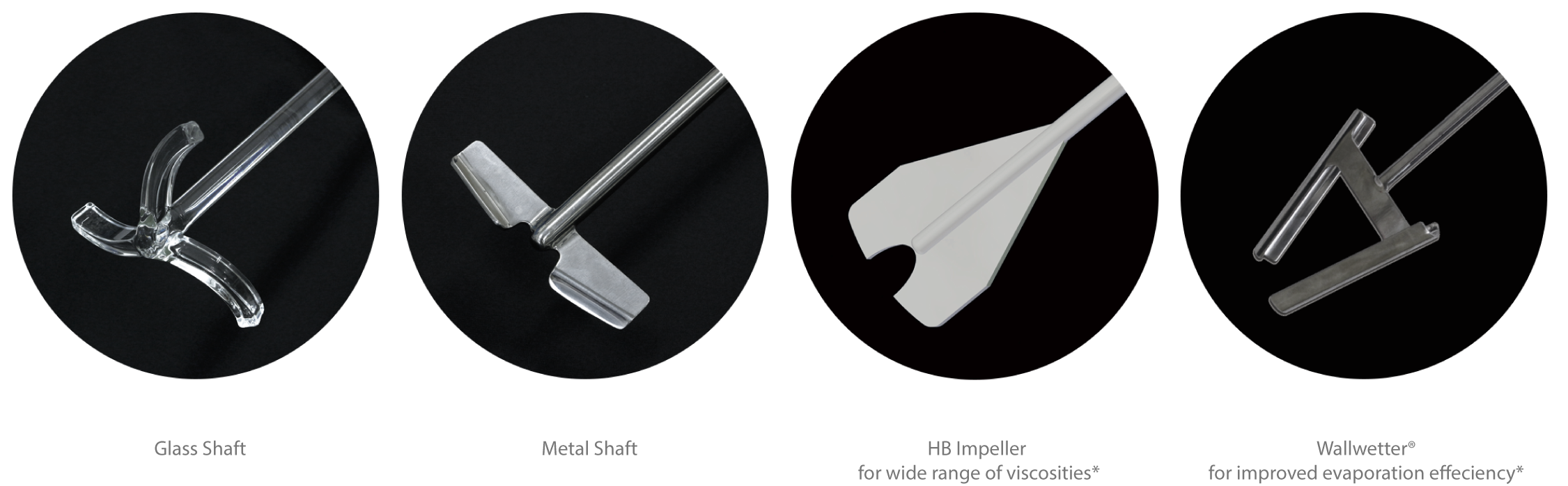

Advanced impeller options

We provide advanced impeller designs for unique mass flow patterns, and accommodate requests for fabricating other configurations to suit your application. We offer the following impeller options:

HB Impeller is useful in achieving high mass transfer in the vessel whilst stirring viscous reactants. If HB impeller is opted for, the temperature probe cannot be inserted from the reactor lid. A special drain valve (available from AGI) with integrated temperature probe must be used if temperature monitoring is required.

Wall wetter is a special impeller configuration that utilises all of the available surface area for evaporating volatile components in the reaction mixture. It does so by spraying the reactants over the vessel wall while rotating. The evaporation rate is greatly improved while using Wallwetter. A special drain valve (available from AGI) with integrated temperature probe must be used if temperature monitoring is required.

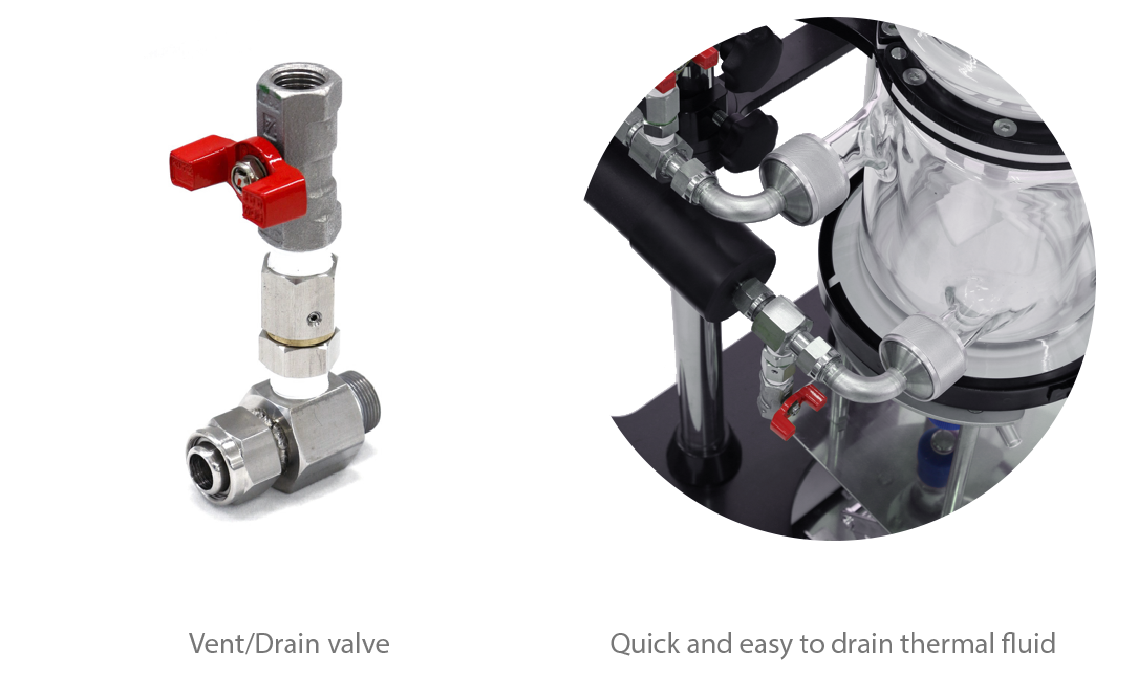

Vent and drain valves

In situations such as frequent changing of vessels or heat transfer fluid, having a vent and drain valve in the jacket outlet and inlet is highly beneficial. They allow you to drain the heat transfer fluid easily, without spills or leaks. Ultimately, this allows you to maintain a clean work space with no oil residue.

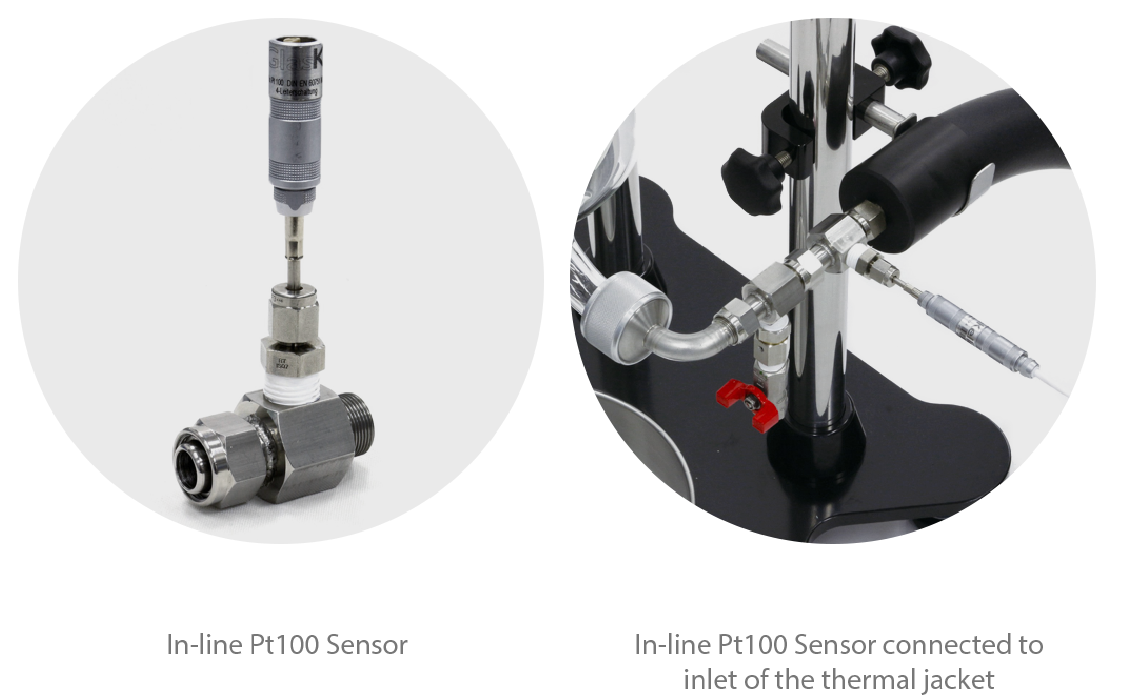

HTF in-line Pt100 sensor

Pt100 sensors installed at the inlet and outlet of the vessel jacket help to measure the exact amount of energy absorbed or released by the process. The data obtained helps you to understand the process dynamics in relation to thermal energy at various stages. This data can serve as the preliminary source of information for planning energy requirement for process scale-up.

Note: AGI supplies only the Pt-100 inline sensor. Datalogger is not under our scope of supply.

Something else in mind?

At AGI, we can help to find the best solution for you. If you have additional requirements or a design already in mind, feel free to send us a message and/or drawing so that we can understand your process better and provide you with a customised product that meets your exact needs.